New Equipment on Glenallachie Bottles - Blog Post

New Equipment on Glenallachie Bottles - Blog Post

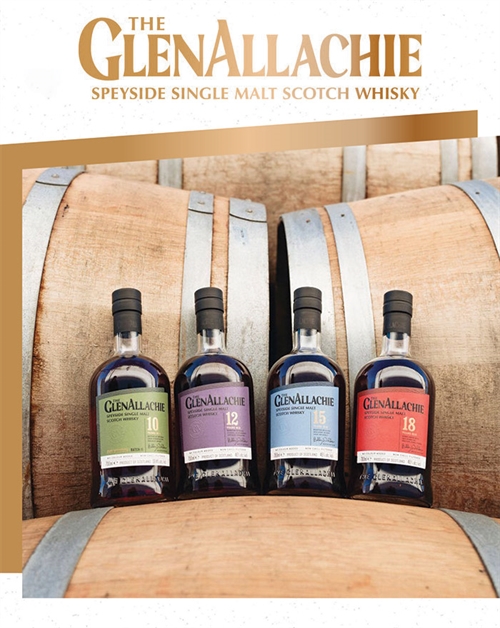

Today, February 20, 2024, The GlenAllachie unveils a refreshed look for its range of single malt whiskies, along with a new logo and visual identity.

With whisky legend Billy Walker at the helm and his over 50 years of experience, the independent Speyside distillery is known for its high quality and innovative approach to cask maturation.

Since the distillery's first core-range product hit the market in 2018, there has been incredible progress, and especially in Denmark, it has become a recognized and beloved whisky brand among whisky enthusiasts. Therefore, it is time for a refresh in both design and identity to symbolize the brand's evolution. Along with the stunning new packaging, there is also a new and updated storytelling about the strong team behind the production of the golden drops.

Same great whisky - better overview

Although the core-range series now changes its appearance, the same familiar and popular whisky is found in the bottles. However, it is a new batch of 10 years old.

In the future, the distillery's many special and limited releases will be grouped under the name 'Wood Collection'. GlenAllachie 8 Years Old is discontinued. The first 4 variants are available in new packaging. By March/April, we should hopefully have 30 Years Old in stock, followed by the first Wood Collection.

Quality over Quantity

With a capacity to produce four million liters of alcohol (LOA) annually, Glenallachie made the decision to reduce their production to one million LOA to focus solely on spirit quality. By lowering production, they now have the luxury of time, allowing for a lengthy fermentation period of 160 hours - around three times the industry average - for a more complex, flavorful distillate.

Cask Innovation

Being independent gives Glenallachie unlimited opportunities for complex and creative cask experimentation. Their hard-earned network of connections with niche producers has opened doors for them to acquire an outstanding inventory of not only the rarest casks but also those of the finest quality from around the world. There can be no compromise in the pursuit of exceptional quality.

Collaboration

In the experienced hands of Billy Walker, a culture of precision, patience, and perseverance has been instilled in his small yet skilled team of whisky experts. By working together, every element of production is optimized to provide complex layers of character. The result of seamlessly coordinated collaboration is a range of carefully crafted and cask-matured whiskies.

Honesty & Integrity

Their values are at the forefront of everything they do; therefore, they proudly bottle all their expressions at a minimum of 46% ABV or higher, without adding caramel or chill filtering the whisky. This allows the authentic quality and character to shine through.

Malting & Production

The process of malting involves steeping barley in water and spreading it out over a malting vessel to germinate. This allows the conversion of starch to sugar to begin. The barley is then dried in an oven to prepare it for malting.

As a traditional unpeated distillery, the malted barley used for The GlenAllachie single malt Scotch whisky comes from local producers based on the Moray Firth coast. They have nine malt bins, each storing 30 tons of malted barley.

They use the original Porteus mill, installed in 1967, to produce 9.4 tons of "grist" for each "production". This type of mill is notoriously reliable; so much so that Porteus went out of business as repairs and replacements were not needed.

The ground malted barley, or 'grist', is mixed with hot water in their 9.4-ton semi-lauter mash tun. The purpose of 'mashing' is to produce as much fermentable sugar as possible. To maximize sugar extraction, they use a four-water cycle for each 'mash', unlike the more common three, while using the same amount of water per kilogram of 'grist'. The resulting liquid, called 'wort', is rich in fermentable sugar, which is important for the next stage in the process.

The 'wort' passes from the mash tun, being cooled on the way, to one of their eight stainless steel fermentation vessels to begin the fermentation process by adding yeast. The yeast they use is selected for its ability to ferment the type of sugar produced when malted barley is ground and 'mashed'. At The GlenAllachie Distillery, they ferment for a lengthy period of 160 hours to develop esters and other flavor compounds that add extra character to their whisky. The resulting liquid is called 'wash'.

Once the "wash" is fermented, it is transferred to the distillery for distillation. They use a traditional double distillation process, but since they have a 'low wines' and 'feints' receiver for each set of wash and spirit stills, they achieve better consistency of strengths and volumes between production runs. This is important in Billy's quest for absolute spirit perfection.

They currently fill at the industry standard of 63.5% as well as 68.5% ABV, in virgin, 1st, and 2nd fill casks to extract carefully considered flavor characteristics from the wood at each strength. They never use casks beyond second fill to ensure that the wood has optimal flavor impact on the whisky.

With 16 warehouses holding an impressive inventory of 50,000 barrels on-site, they have full control over the entire process from start to finish. Master Distiller Billy Walker uses his unique network of contacts to source the finest quality barrels from around the world. The spirit is continuously monitored as it develops to assess whether it should be re-racked into a new barrel type to add additional layers of complexity or if it has reached the 'sweet spot': the perfect balance between distillery character and wood influence.